Laser cutting machines deliver precise, clean, and efficient cutting for complex shapes, ensuring high-quality results in industrial fabrication.

Our Services

Comprehensive manufacturing solutions for your industrial needs

Aluminum Die Casting

Aluminum die casting ensures precise, durable components with excellent surface finish. It delivers consistent quality for automotive, industrial, and engineering applications.

Ferrous & Non Ferrous Casting

Ferrous and non-ferrous casting delivers high-quality metal components using advanced molding and melting techniques.

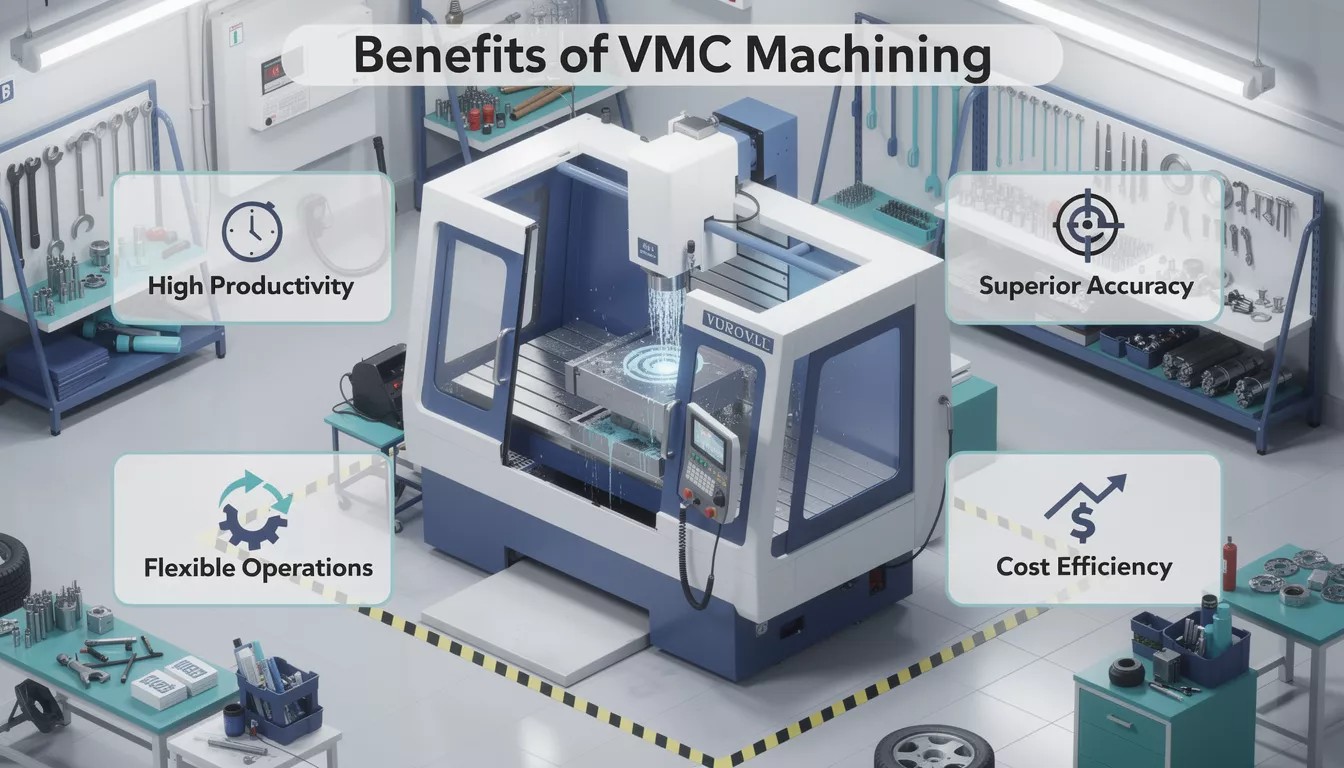

VMC Machining

Advanced VMC machining capabilities with multi-axis precision for tight tolerances and complex part geometries.

Die Manufacturing

Die manufacturing involves creating high-precision molds designed to shape metal or plastic components with accuracy and consistency.

Patterns Manufacturing

We provide high-precision pattern manufacturing using advanced materials and techniques to ensure accurate and reliable castings.

Laser Cutting & Fabrication

Our Machinaries & Equipments

Equipped with advanced technology to ensure precision, efficiency, and reliability in every process

Melting Services

AMS-MCV-450 Vertical Machining Center

Joythi CNC Vertical Machining Center

Drilling Machine Model-EIFCO

The Drilling Machine Model-EIFCO is a robust and reliable machine designed for accurate drilling operations on various materials. It features a sturdy construction, smooth spindle operation, and easy speed adjustment, making it ideal for workshop and production use.

Conventional Lathe Model-Micro Rajkot

The Conventional Lathe Model-Micro, Rajkot is a versatile machine designed for precise turning, facing, and threading operations. Built with durable components and smooth control mechanisms, it is ideal for both educational and small-scale industrial applications.

Laser Cutting Machine

CNC Router Machine

About Us

Founded in 2018, SoNa Precitech was established with a clear and focused vision—to become a leading and trusted Tool Room in Shimoga by consistently delivering precision, innovation, and value. Quality defines our identity, and every solution we provide reflects our commitment to engineering excellence, accuracy, and dependable performance. From the smallest component to complex tooling solutions, we maintain strict quality standards to ensure flawless results and timely delivery.

Our strength lies in our skilled workforce and modern, well-equipped infrastructure, enabling us to adapt to evolving industry requirements with efficiency and confidence. We offer complete end-to-end services, beginning with concept development and design, progressing through tool manufacturing, and culminating in the delivery of neat, ready-to-use products tailored to customer needs. As strategists, designers, and problem solvers, we work closely with our clients to understand their challenges and transform ideas into practical, high-quality solutions. Agile, responsive, and customer-focused, Sona Precitech is committed to building long-term partnerships that support growth, reliability, and industrial success.

7+

Years Experience

500+

Projects Completed

30K+

Sq. Ft. Facility

30+

Team Members

Infrastructure & Facilities

State-of-the-art manufacturing facilities and quality assurance labs

Aluminum casting Foundry

Reliable aluminum casting foundry delivering precision-engineered components.

Wood Pattrens

Durable wood pattern work for molds

VMC Units

Precision machining centers

Designing

Innovative industrial material designing for stronger, smarter product solutions.

Conference Room

Conference room for clear communication, online support, and timely customer service.

Laser Cutting Machine

Laser cutting machines deliver high-precision cutting

×

Client Testimonials

Faheem

Exceptional quality castings and timely delivery every time. Their precision and finishing standards are truly impressive. We trust them completely for all our high-volume production needs.

Likhith G M

The team’s technical expertise helped us reduce defects and improve efficiency. Their commitment to quality makes them stand out in the industry. A reliable partner for all our ferrous and non-ferrous casting requirements

Madhu Sudan

From prototype to final production, the support was outstanding. They provided consistent quality and met every deadline without fail. Highly recommended for any manufacturer seeking dependable casting solutions.

Industries We Serve

Serving diverse sectors with precision manufacturing solutions

Automotive

Engine components, chassis parts, and precision assemblies

Aerospace

Aircraft components, turbine parts, and flight-critical castings

Heavy Machinery

Construction equipment, mining machinery, and industrial gear

Construction

Structural components, building frames, and infrastructure parts

Energy & Power

Power generation components, turbines, and energy systems

Agriculture

Farm machinery parts, irrigation components, and equipment

Marine

Marine engine parts, ship components, and maritime hardware

General Manufacturing

Custom solutions for diverse industrial applications

Latest Updates

Insights and news from the manufacturing industry

How Casting Improves Production Efficiency

Discover how modern casting techniques can significantly reduce production costs and lead times while maintaining quality standards.

Benefits of VMC Machining

Explore the advantages of VNC machining for precision manufacturing, including accuracy, repeatability, and complex geometry capabilities.

Choosing the Right Metal for Fabrication

A comprehensive guide to selecting the optimal metal alloys for your fabrication projects based on application requirements.

Frequently Asked Questions

Common questions about our manufacturing services

What is your minimum order quantity?

Our minimum order quantity varies depending on the service and material. For standard casting, we typically require a minimum of 50 units, while custom fabrication projects can start from single-piece prototypes. Contact us for specific MOQ requirements for your project.

What material options do you offer?

We work with a wide range of metals including aluminum, steel (carbon and stainless), cast iron, bronze, brass, titanium, and various specialty alloys. We can source specific materials based on your requirements and provide material certifications upon request.

What are your typical production timelines?

Production timelines depend on order volume, complexity, and material availability. Standard orders typically take 4-8 weeks, while prototype development can be completed in 2-3 weeks. Rush orders may be accommodated with expedited processing. We provide detailed project timelines during quotation.

What tolerance and accuracy can you achieve?

Our CNC machining capabilities can achieve tolerances as tight as ±0.001 inches (±0.025mm), while casting tolerances typically range from ±0.005 to ±0.020 inches depending on the process. We work closely with clients to determine optimal tolerances for cost-effectiveness and functionality.

Do you handle shipping and delivery?

Yes, we provide comprehensive logistics services including packaging, crating, and shipping via preferred carriers. We can accommodate both domestic and international shipments and work with your preferred freight forwarders. Shipping costs are calculated and included in project quotations.

What quality testing methods do you use?

Our quality assurance includes dimensional inspection using CMM (Coordinate Measuring Machine), material composition verification, hardness testing, surface finish analysis, and visual inspection. We also offer X-ray inspection, dye penetrant testing, and ultrasonic testing for critical applications. All testing protocols comply with relevant industry standards.

Our Trusted Clients

Contact Us & Request a Quote

Get in touch with our team for your manufacturing needs

Contact Form

Contact Information

Address

#25/02, KIADB Industrial Area, Machenhalli, Nidige Post, Shimoga-577222

Phone

+919916067224

+917411057172

Mon-Sat: 10:00 AM - 7:00 PM IND

sonaprecitech@gmail.com